Features

The introduction of wafer biscuit heating oven:

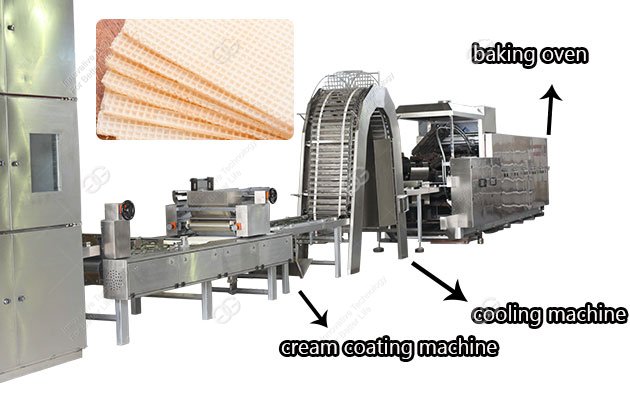

This is very important equipment in the wafer production line. The wafer baking system uses LPG for heating of the baking plates. It is controlled by a PLC made by SIEMENS brand. The functions of the baking oven are fully automatic from spreading batter on the plates to the procedure of baked wafer sheets coming out of the oven. Baking wafer is even and produces good quality wafer sheets for next procedure. In PLC, there is a PID controller which is used to control the temperature of the baking plates automatically. The collection of required signal of PID is supplied by infrared sensor which is produced by RAYTEK of U.S.A. The oven status display and the data reset are supplied by SIEMENS by Japan. Contactor switch is supplied by SCHENEIDER Company in China. The stepping wheel bearings of the mould rack are SKF Explorer made in France. The pressing roller bearings are SKF Explorer made in Austria. The pneumatic components are supplied by FESTO/SMC. The main drive will be SEW Eurodrive of German brand. There is an automatic spurring-cleaned device at the bottom of the baking oven. There is second pressure relief valve from Madas. The floating system is new type. The pressing system, opening system and tension system are improved about the heat-treatment. There is a safety cover for batter inductive switch.

This is very important equipment in the wafer production line. The wafer baking system uses LPG for heating of the baking plates. It is controlled by a PLC made by SIEMENS brand. The functions of the baking oven are fully automatic from spreading batter on the plates to the procedure of baked wafer sheets coming out of the oven. Baking wafer is even and produces good quality wafer sheets for next procedure. In PLC, there is a PID controller which is used to control the temperature of the baking plates automatically. The collection of required signal of PID is supplied by infrared sensor which is produced by RAYTEK of U.S.A. The oven status display and the data reset are supplied by SIEMENS by Japan. Contactor switch is supplied by SCHENEIDER Company in China. The stepping wheel bearings of the mould rack are SKF Explorer made in France. The pressing roller bearings are SKF Explorer made in Austria. The pneumatic components are supplied by FESTO/SMC. The main drive will be SEW Eurodrive of German brand. There is an automatic spurring-cleaned device at the bottom of the baking oven. There is second pressure relief valve from Madas. The floating system is new type. The pressing system, opening system and tension system are improved about the heat-treatment. There is a safety cover for batter inductive switch.

The features of automatic heating machine:

1. the whole shell of the production line adopts 304 stainless steel in accordance with the health and safety standard.

1. the whole shell of the production line adopts 304 stainless steel in accordance with the health and safety standard.

2. the electricity and transmission components are all used siemens, mitsubishi, touch screen to ciontrol and adopts the interenational brand germany sew, skf to make the whole line steadily.

3. in according to the clients' requirements, we can make a wide range of size and shape cream (chocolate ) filled wafer biscuit full automatically.

Technical Data

| Model | KHG-27 | KHG-39 | KHG-45 | KHG-51 | KHG-65 | KHG-69 |

| Mould | 27 | 39 | 45 | 51 | 65 | 69 |

| Baking Plate Size | 470*325 | 470*325 | 470*325 | 470*325 | 470*325 | 470*325 |

| Capacity(pcs/min) | 14 | 20 | 23 | 26 | 33 | 35 |

| Machine Size(contains no smoke tube) | ||||||

| L(mm) | 6000 | 8260 | 9400 | 10550 | 13200 | 14000 |

| W(mm) | 1700 | 1700 | 1700 | 1700 | 1750 | 1760 |

| H(mm) | 2300 | 2300 | 2300 | 2300 | 2300 | 2300 |

| Weight(t) | 10 | 12 | 13 | 14 | 17 | 20 |

Leave Message

Related Machine