Features

The Introduction of Wafer Biscuit Making Machine

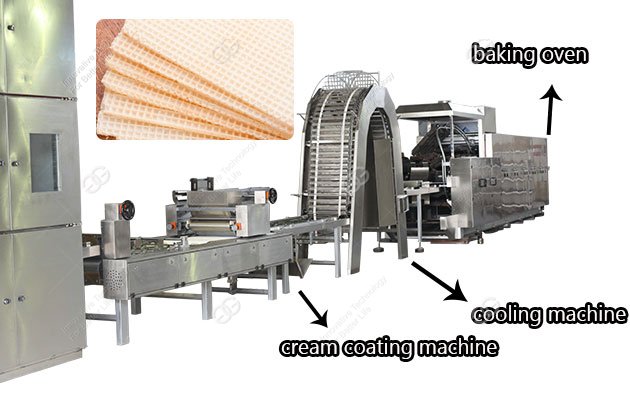

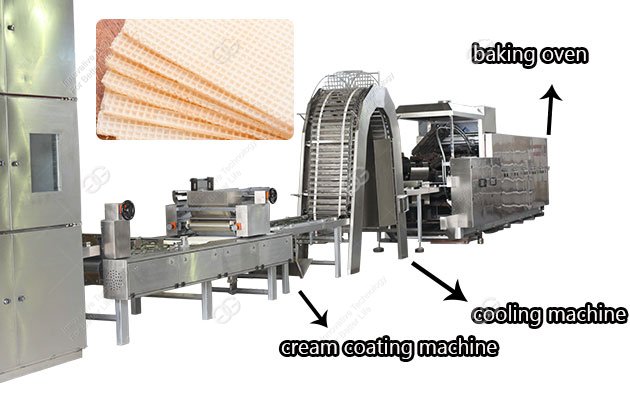

This wafer sheets making machine is a fully automatic production line, mainly used for processing wafer sheets, edible wafer, chocolate wafer biscuits, etc. The important parts of this plant are baking, cooling, cutting, forming and packing, each process is seamlessly connected for wafer biscuits continuous production.

Characteristics of Wafer Sheets Machine

Process of Wafer Sheets Making Machine

Advantages of Wafer Biscuit Making Machine

This wafer sheets making machine has the features of reliable performance, compact structure, small occupation, high yield, lower energy consumption, convenient maintenance, simple operation. It has two kind of heating methods: electric and gas, it widely sold to many countries, Malaysia, Canada, Indonesia and so on.

This wafer sheets making machine is a fully automatic production line, mainly used for processing wafer sheets, edible wafer, chocolate wafer biscuits, etc. The important parts of this plant are baking, cooling, cutting, forming and packing, each process is seamlessly connected for wafer biscuits continuous production.

Characteristics of Wafer Sheets Machine

1. Fully automatic operation, the entire wafer sheet production line of wafer biscuits requires only 3-4 people and can be produced continuously.

2. Composed of cream mixer, baking oven, cooling machine, cutting machine, cream coating machine, wafer cleaning equipment, etc.

3. The drive motor adopts German SEW and the bearing adopts SKF Fracne, which is sturdy and durable. PLC control, automatic production process, simple operation.

4. The heating method of wafer sheet baking machine are electric and gas, also can be customized according to customers' demand.

Process of Wafer Sheets Making Machine

Advantages of Wafer Biscuit Making Machine

1. Advanced technology: The production line is developed on the basis of the advanced structure of similar products at home and abroad.

2. Electricity and gas heating energy: Wafer equipment products developed exclusively in China, using electric heating or gas heating as the heat source.

3. It successfully solves the problems of high production cost and large color difference on the surface of the biscuit in the production of wafer biscuits.

4. The parts of the commercial wafer biscuit making machine in contact with food are made of 304 stainless steel, which is clean and hygienic.

Main Equipment:

Main Equipment:

1. Beater: including single-color or double-color beating and pumping devices, raw materials are mixed into batter.

2. Tunnel oven: including single-color or double-color pulp supply series, with electric heating and gas heating.

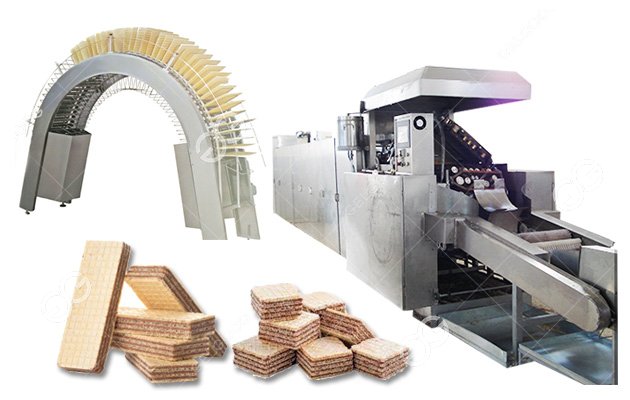

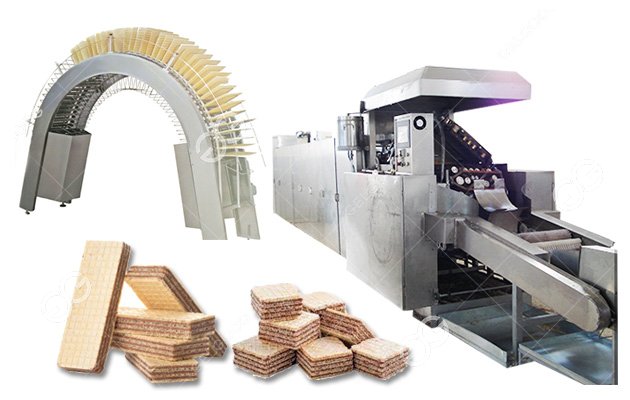

3. Wafer sheets screening machine: Screen out unqualified wafers, and high-quality wafer biscuits continue to the next step.

4. Cream coating machine: The lamination forms mainly include reciprocating type and turning plate type, which can be coated with single and double flavors.

5. Vertical freezer: use air-cooled unit to cool, the cooling temperature can reach below 0℃, which is conducive to subsequent packaging.

6. Wafer sheet cutting machine: It adopts pneumatic reciprocating structure, and the cutter is made of wear-resistant material, which is simple and durable.

This wafer sheets making machine has the features of reliable performance, compact structure, small occupation, high yield, lower energy consumption, convenient maintenance, simple operation. It has two kind of heating methods: electric and gas, it widely sold to many countries, Malaysia, Canada, Indonesia and so on.

Technical Data

| Model | Tunnel Oven(L) | Whole Line(L) | Power | Consumption LNG | Capacity |

| GGWH27 | 6000 mm | 22000 mm | 5.52 kw | 21 m3/h | 14 pcs/min |

| GGWH33 | 7150 mm | 23150 mm | 5.52 kw | 26 m3/h | 17 pcs/min |

| GGWH39 | 8300 mm | 24300 mm | 5.52 kw | 30 m3/h | 20 pcs/min |

| GGWH45 | 9450 mm | 25450 mm | 5.52 kw | 35 m3/h | 23 pcs/min |

| GGWH51 | 10600 mm | 26600 mm | 5.52 kw | 40 m3/h | 26 pcs/min |

| GGWH65 | 13300 mm | 29300 mm | 8.12 kw | 50 m3/h | 33 pcs/min |

| GGWH69 | 14000 mm | 30000 mm | 8.12 kw | 54 m3/h | 35 pcs/min |

| GGWH75 | 16000 mm | 35400 mm | 8.12 kw | 58 m3/h | 38 pcs/min |

Leave Message

Related Machine