Features

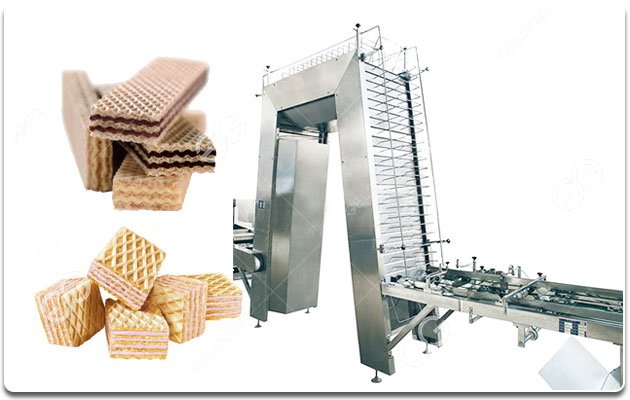

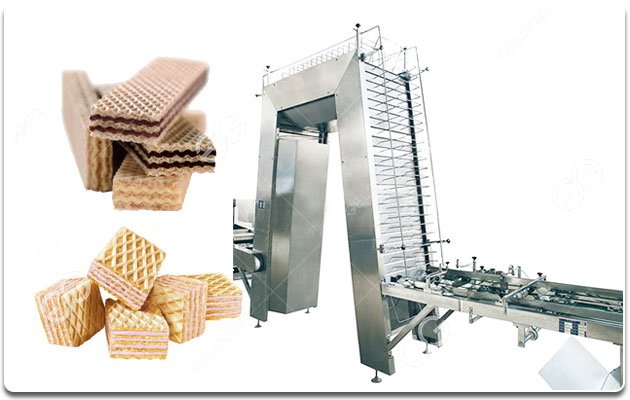

The automatic wafer biscuit production line uses gas heating as the heat source, and is a product specially developed and designed for small and medium-sized wafer biscuits manufacturers. It can produce high-quality wafers of various sizes.

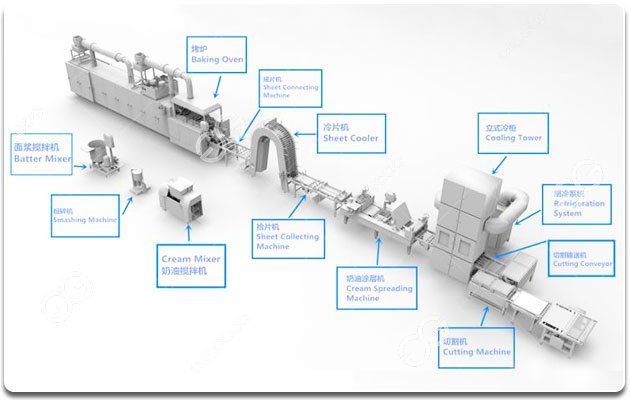

Composition of Wafer Equipment:

Composition of Wafer Equipment:

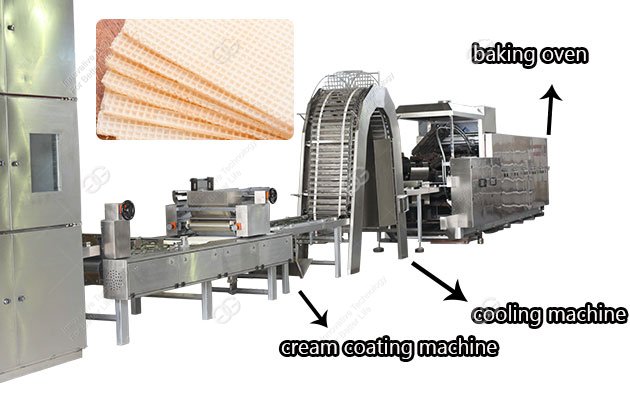

The wafer production line mainly contains batter mixer, baking oven, cooling machine, cream spreading machine, conveyor, cutter machine, cream mixer, wafer smashing machine, wafer biscuit packing machine.

Advantages of Wafer Production Line

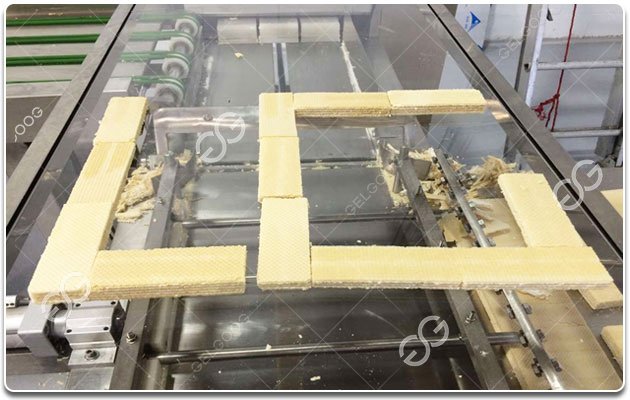

1. The surface color of the wafers produced is uniform, and the cream is evenly spread, and the size is uniform.

2. This wafer biscuit making machine has two types cutting methods: wire cutting and knife cutting, wire cutting to ensure a smoother cutting.

3. Gas heating is generally recommended for wafer baking ovens in the production line, which is more affordable.

4. The wafer biscuit machine runs smoothly, without abnormal noise, and will not affect the lives and work of people around it.

In order to meet the needs of more users, the company has developed a wafer line with many models, and manufacturers can choose the one that suits their needs. Combining advanced technology at home and abroad, successfully solved the problem of high production cost and large color difference on the surface of wafer biscuits in the production of wafer biscuits.

Video of Wafer Biscuit Manufacturing Process

Wafer Biscuit Production Process:

Batter Pulping---Baking---Wafer Sheet Forming--Cooling---Cream Mixing---Cream Spreading---Layering---Wafer Biscuit Cutting---Wafer Biscuit Forming---Wafer Biscuit Packaging

Characteristics of Wafer Biscuit Making Machine

1. This production line is specialized in making high quality wafer biscuit, no color difference, bright colors.

2. The processing process is simple and the this wafer machine is fully automatic, save labor cost.

3. All parts of wafer biscuit production line in contact with food are made of stainless steel to ensure food hygiene.

4. The motors, bearings, PLC and other components adopt international famous brand, can use for a long time.

5. This wafer making machine uses special energy conservation design, reduce energy consumption.

6. This wafer biscuit manufacturing machine according to HACCP design, with high production effeciency, stable and reliable operation, long service life. All parts contacting with the food are made from SUS304 and food-grade materials.

7. Whole line with fully automatic controlled, easier operation and save the labor costs(only need 4-5 workers to operate the machines). We not only provide high quality and factory price machines, but also quality service.

The automatic wafer biscuit production line has the characteristics of reliable performance, high output, low energy consumption, convenient maintenance and simple operation. Often sold to Iran, UAE, Saudi Arabia, the United States, Canada, Algeria, Bangladesh, Tunisia, Sri Lanka and so on.

As a professional biscuit production line manufacturer, the products sold by our company are independently designed, produced and shipped, saving customers the cost of intermediate links. If you need more details, please contact us. Email: lisa@machinehall.com, whatsapp/wechat: +8615515571373.

Technical Data

| Model | GGWH-27 |

| Capacity | 91kg/h |

| Power | 5.52kw |

| Air compression | 36m³/h |

| Length | 6m |

| Weight | 13t |

Leave Message

Related Machine