Features

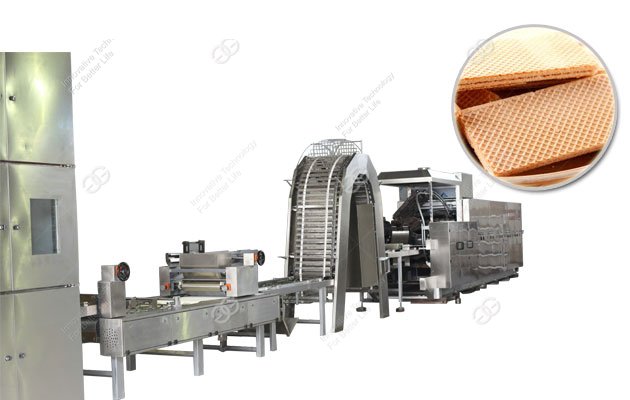

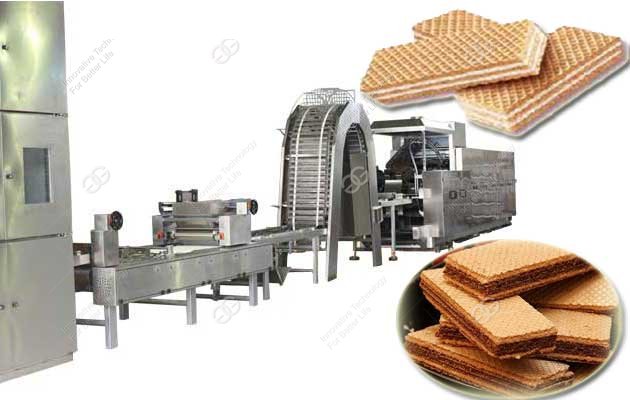

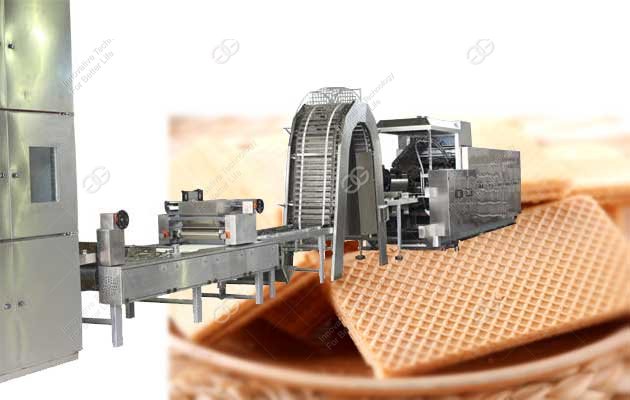

Wafer Biscuit Making Machine Description:

This production line is mainly used for producing all kinds of high quality waffles. This production line has high automation level, saves human resources and conforms to food machinery and food safety and health standards. Granville cake production line to meet the high-end market demand for biscuits, with great market potential. Production line of the main equipment has Granville cake oven, cream coating machine, wafer biscuit forming cutting machine.

This production line is mainly used for producing all kinds of high quality waffles. This production line has high automation level, saves human resources and conforms to food machinery and food safety and health standards. Granville cake production line to meet the high-end market demand for biscuits, with great market potential. Production line of the main equipment has Granville cake oven, cream coating machine, wafer biscuit forming cutting machine.

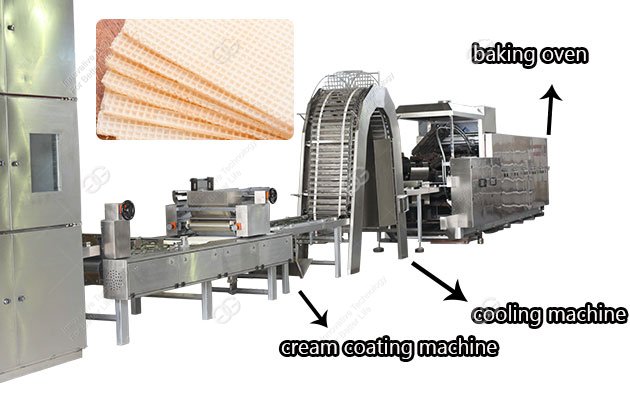

Tunnel Type Biscuit Heating Oven:

For large-scale production of 27~85 tablets, the number of templates set. The slurry, baking, out of the automatic completion. The oven uses double chamber structure. The heating effect of the furnace chamber is better, and the mechanical part of the outer furnace is longer in service life. The control part adopts the Mitsubishi or Siemens Color touch screen. It can display and set the running speed of the baking board, the temperature of the baking plate, the control of the mechanical part, the slurry quantity and the ignition. Gas system components are used in international brand-name products, the machine bearings are used in Germany SKF high temperature bearings, the whole machine motor, reducer are used in Germany sew, baking board using gray cast iron made. Long service life, the best effect of the use of heat energy, wafer coloring evenly.

Wafer cream coating Machine:

The wafer is automatically coated with cream or other material, and the wafer is folded into multilayer sandwich wafer. The machine uses imported stainless steel German sew motor PU food conveyor belt, the control part of the use of Mitsubishi or Siemens color touch screen. You can set the production speed and set the number of layers for the block. The number of layers that can be set up for the wafer is: 2~6 layer, oil storage bucket belt heating device.

Wafer-Stacking machine of biscuit

Laminated machine is the equipment used in matching with biscuit forming machine. The machine is the dough to press the skin through the reciprocating operation, the car repeatedly stacked layer, the number of floors, the allocation of crisp devices, will be laminated after the dough to the molding machine, the machine produced by the biscuit hierarchy, crisp taste, crisp, is to improve the quality of biscuits, the main equipment, is the production of biscuits to play the necessary equipment.

Main characteristics:

1. Good rolling effect and uniform thickness of the pressed surface.

2, the control systematization, the operation is convenient, the pressure piece thickness (adjusts the thickness to display by the numeral) and the overlapping number of times may adjust arbitrarily.

Wafer biscuit Forming Machine

Forming machine is an important equipment of biscuit production line, this machine can be equipped with two types of roll-cutting and roller printing, also can be combined configuration. function can be any combination, can be configured into the furnace seat, sesame, sugar material strewing machine, advanced structure, rolling into the production of ductile biscuits, roller printing molding used to produce crisp biscuits, molding machine, in the same production line can produce various grades of multi-color biscuits, color, incense, taste in one, and the machine production flexibility, can be thick, thin adjustment, The advantages of low noise and high efficiency. Suitable for producing all kinds of high, mid-range, salty, sweet, thick, thin biscuits.

Technical Data

| Equipment Name |

Dimension (mm) |

Power (kw) |

| Batter Mixer | 1720*1200*930 | 4.5 |

|

Gas Baking Oven (GGHG-27) |

6740*1600*2260 | 5.52 |

| Wafer sheet connecting machine | 1050*700*940 | 0.18 |

| Vertical-type wafer sheet cooler LPL | 3250*700*2780 | 0.37 |

| Sheet Collecting Machine | 2000*700*825 | 0.18 |

| Cream spreading machine | 3000*1160*1300 |

380V-2.24 220V-2 |

| Vertical cooling tower | 3140*1160*2700 | 1.21 |

| Cold Blower | 2200*1100*1800 | 10.75 |

| Laminator/Transportation system | 1115*700*870 | 0.18 |

| Mechical Blade-type Cutting Machine | 2000*1700*880 | 0.75 |

| Distributing machine | ||

| Separating conveyor | 1840*850*1350 | 0.18 |

| Cream Mixer(with water jacket) | 1830*700*1240 | 5.05 |

| Smashing machine | 670*660*1200 | 3 |

Leave Message

Related Machine