Features

The main purpose of cheese wafer making machine is to make high-quality wafer biscuits of uniform size, which is specially developed by the manufacturer for small and medium enterprises. And it is also exported to Indonesia, South Africa, Saudi Arabia, USA, Afghanistan, etc.

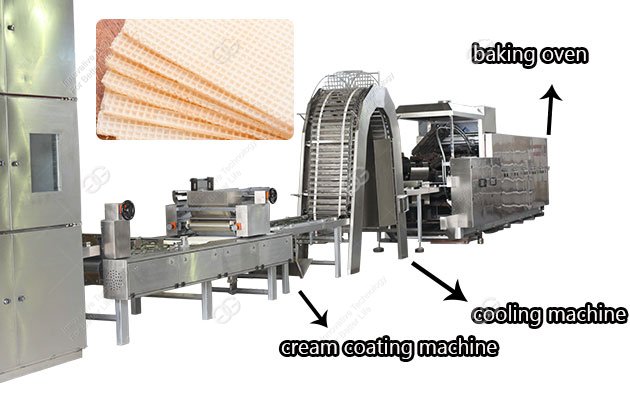

Process Flow of Wafer Biscuit Manufacturing:

Batter mixing---biscuit sheet baking---cooling biscuit---coating cream for wafer sheet---cutting into wafer biscuit of the same size---packaging.

Cheese Wafer Making Machine Characteristics:

Advantages of Cheese Wafer Biscuit Machine

Process Flow of Wafer Biscuit Manufacturing:

Batter mixing---biscuit sheet baking---cooling biscuit---coating cream for wafer sheet---cutting into wafer biscuit of the same size---packaging.

Cheese Wafer Making Machine Characteristics:

① The heating oven has different heating methods: electric heating and gas heating. PID automatic temperature control, baking the wafer biscuit of uniform color.

② High-quality materials: the frame is nodular cast iron, the baking pan is heat-resistant cast iron, standard baking pan size is 325*470 mm, and can be customized.

③ The mixer machine is made of all stainless steel. The dynamic and static ring blade type dough mixer can beat 25 kg of flour into dough in 3 minutes.

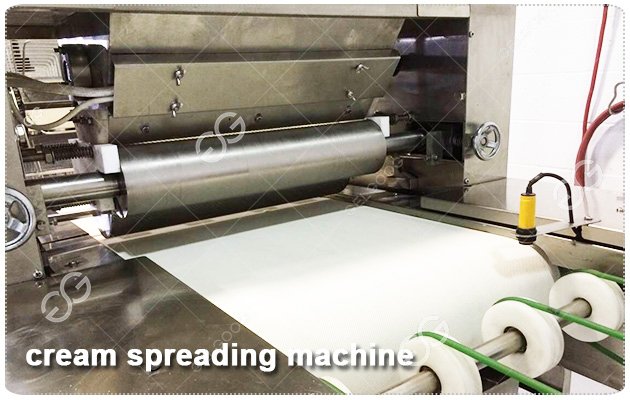

④ The frame of the cream coating machine is a galvanized steel beam structure, coating head is a combined structure, which is easy to assemble, disassemble and clean.

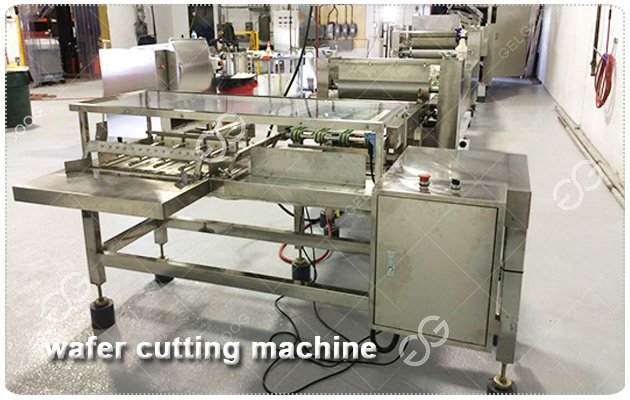

⑤ The cutting machine is a steel wire or blade cutting machine, with a standard cutting speed of up to 8 books, fast speed and uniform cutting.

Indonesia Cheese Wafer Making Machine Video:Advantages of Cheese Wafer Biscuit Machine

1. This line is a small-scale wafer processing equipment, mainly used to produce various types of high-quality cheese wafers with large capacity.

2. It is integrated with foreign advanced technology and innovatively improved. After years of continuous development, it has become very mature and reliable.

3. In recent years, through continuous technical innovation, the machine has a stable performance and a high degree of automation.

4. This machine greatly reduces the input cost and investment risk, it is a cost-effective production line for wafer block production.

5. It can be customized according to the investor's own sales, output demands. The equipment uses an upright cooling machine, which reduces the footprint.

5. It can be customized according to the investor's own sales, output demands. The equipment uses an upright cooling machine, which reduces the footprint.

Technical Data

| No. | Model | Qty |

| 1 | 21 Mould Electric Baking Oven | 1 |

| 2 | Wafer Sheet Receiver | 1 |

| 3 | Sheet Cooling Machine | 1 |

| 4 | Sheet Picking Machine(choose) | 1 |

| 5 | Cream Spreading Machine | 1 |

| 6 | Wafer Cutting Machine | 1 |

| 7 | Wafer Batter Mixer | 1 |

| 8 | Cream Mixer | 1 |

| 9 | Smashing Machine | 1 |

| 10 | Sugar Grinder Machine | 1 |

| 11 | Air Compressor | 1 |

| 12 | Pillow Type Packing Machine | 1 |

Leave Message

Related Machine