Features

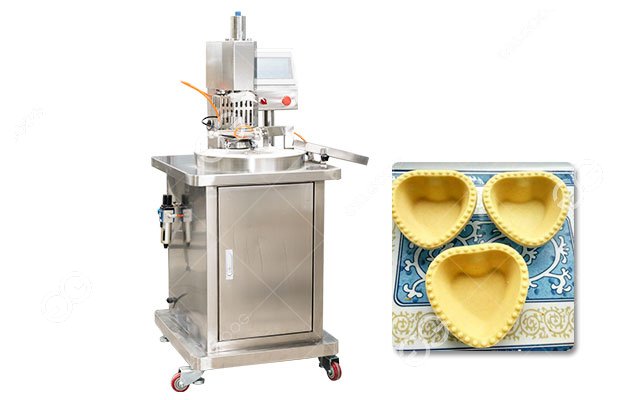

Industrial egg tart crust machine is a special equipment for processing egg tart crusts, it uses non-stick mold to ensure the complete formation of egg tart crusts.

There are different types of tart shells can be produced, such as square shape, heart shape, lace shape and other special types.

This equipment can make tart crusts of different sizes, usually 7 cm, 8 cm, etc. Some special tart skins can also be made by customers' requirements.

Testing Video of Industrial Egg Tart Crust Making Machine

The Characteristics of Egg Tart Crust Making Machine

There are different types of tart shells can be produced, such as square shape, heart shape, lace shape and other special types.

This equipment can make tart crusts of different sizes, usually 7 cm, 8 cm, etc. Some special tart skins can also be made by customers' requirements.

Testing Video of Industrial Egg Tart Crust Making Machine

The Characteristics of Egg Tart Crust Making Machine

1. Small and flexible, this machine covers little space and is very convenient to use.

2. This tart crust machine is made of high quality stainless steel, make sure the fished products are clean and healthful.

3. Adopted PLC performance control, with large capacity of 1500-1800 pcs/h.

4. Industrial egg tart crust machine is easy to operate, fulfill the requirements of process safety.

5. Quick and easy replacement of the molds, suitable for various designed productions.

7. Low energy consumption and noise, this machine has a long service life to use.

Note the following points when operating the egg tart crust making machine

A. Connect the power supply and air supply tube-turn on the power (emergency stop) button-first go to the manual screen to debug the egg tart product-open the automatic switch and press the start button-put the aluminum cup and filling in the mold hole Internal--automatic forming--discharging--complete.

B. Mold replacement steps: first turn off the power, loosen the upper mold screws, then remove the heating coil power, and then loosen the three screws on the disc to remove it. Install a new mold, install the disc, and then install it. The mold is used to test the thickness of the skin in a manual state.

C. The air inlet pressure of the air compressor is 0.6 ~ 0.8Mpa (6 ~ 8 bar).

D. Before replacing electrical or mechanical parts, turn off the power first, and turn off the emergency stop button and power before replacing the mold.

Technical Data

| Model | GGA303-1 |

| Capacity | 1500-1800PCS/H |

| Voltage | 220V,50hz |

| Diameter of Tart | 40-90mm |

| Size | 840*800*1300mm |

| Weight | 130kg |

Leave Message

Related Machine